Hydrogen refueling station for SMALL mobility ( up to 350 bar)

Off Grid Station : 100% autonomous

H2 refuelling station for micro-mobility up to 300 bar

No fixed utilities, disconnected from energy and water networks : 100% autonomous

Upgrade possible to 400 bars

Vehicles : forklifts, site machinery, bicycles, sweepers.

Model 1

Model 2

Technical details of the 300 bar off grid filling station:

Dimensions of station: 1310 x 1345 x 5364 mm

Mass (without storage cylinders): 850 kg

Time of refuelling: 120 bar per minute, allows quick refuelling of H2 bike to 300 bar in approx. 2 minutes

Performances:

Temperature range: -10 °C / 40 °C

Cascade of three pressure sections

Mass of stored gas (H2) at 15°C: 2.5 kg (small type) or up to 5.45 kg (big type), supplied to be stored inside the station

Modularity and capacity of storage:

Inside the station – hydrogen storage cylinders supplied separately, from 108 L up to 252 L

Outside the station – can be expanded by connecting a modular storage with unlimited storage capacity, up to max. available footprint on site

Equipment:

Hydrogen detector

High pressure hydrogen filter

Dispensing by flexible hose and special connection for refuelling 300 bar H2 bikes

PV panel to power a battery and charge the pneumatic compressor to increase the possible number of refuellings (+85 times)

Battery buffer: 2 batteries of 25Ah - 12 V DC

Features:

Energetic independence thanks to PV panels

Automated (electric automation)

RFID identification

No fixed utilities, disconnected from energy and water networks: 100% autonomous

Specifically sized to operate alongside the private sector or municipal infrastructure for bike rental, etc.

Possibility to extend the maximum service pressure up to 400 bar

Manipulation by forklift

Customised colour, graphics and branding (optional)

Refuelling connection: customer´s defined, acc. to type of refueled vehicle

Communication:

Identification badge to unlock the station operation (badge defined by customer)

Fleet monitoring system package – telemetry (optional)

Certification: machine certification - 2006/42/CE, PED certification 2014/68/EU if needed, will be possible after our revision of documents in existing certification

Documentation: package included for delivery contains general arrangement drawing, the operation and maintenance manual, declaration of conformity.

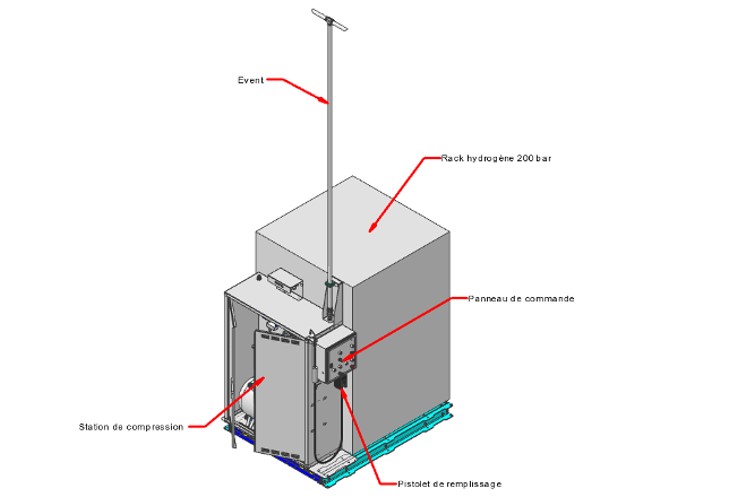

On Grid Station

- With electrical and compressed air connection (for the air compressor)

- Limited to 350 bar.

- Evolution possible at 400 bars: not planned.

- Vehicles: trolleys, construction machinery, bicycles, sweepers, large construction machinery

Configuration and elements integrated into the station:

- H2 distribution station at 350 bar;

- Flexible + Break Away for distribution;

- Hydrogen compressor;

- Control Panel ;

- Pressure control valve; Pneumatically operated valve; Buffer storage;

- Pressure sensor; Check valve ; Regulator ;

- TPRD + PRV; Manometer;

- Grounding;

- Reception platform for the gas rack;

- Requires a compressor for air supply;

- Need to be connected to the electric current;

Station characteristics:

- Minimum hydrogen pressure to be supplied to the station: 40 bar;

- Maximum hydrogen distribution pressure: 350 bar;

- Recommended hydrogen distribution pressure: 320 bar (automatic limitation);

- Minimum and maximum temperature of use: -10°C / +50°C;

- Air supply (for guaranteed filling time: 1,500 L/minute; (Minimum)

- Weight of the station (without storage): 550 kg;

- Station dimensions (L x W x H): 1780mm x 1400mm x 5300mm.

The Station will be CE certified according to the Pressure Equipment Directive. The necessary documentation for setting up a CE hydrogen distribution station at 350 bar will be provided.

ROTH2 will take care of the training of ATEX level 2 approved users.